- +86 15030729981

- hebeizeus@163.com

- Economic Development Zone, Cang City, Hebei Province, China

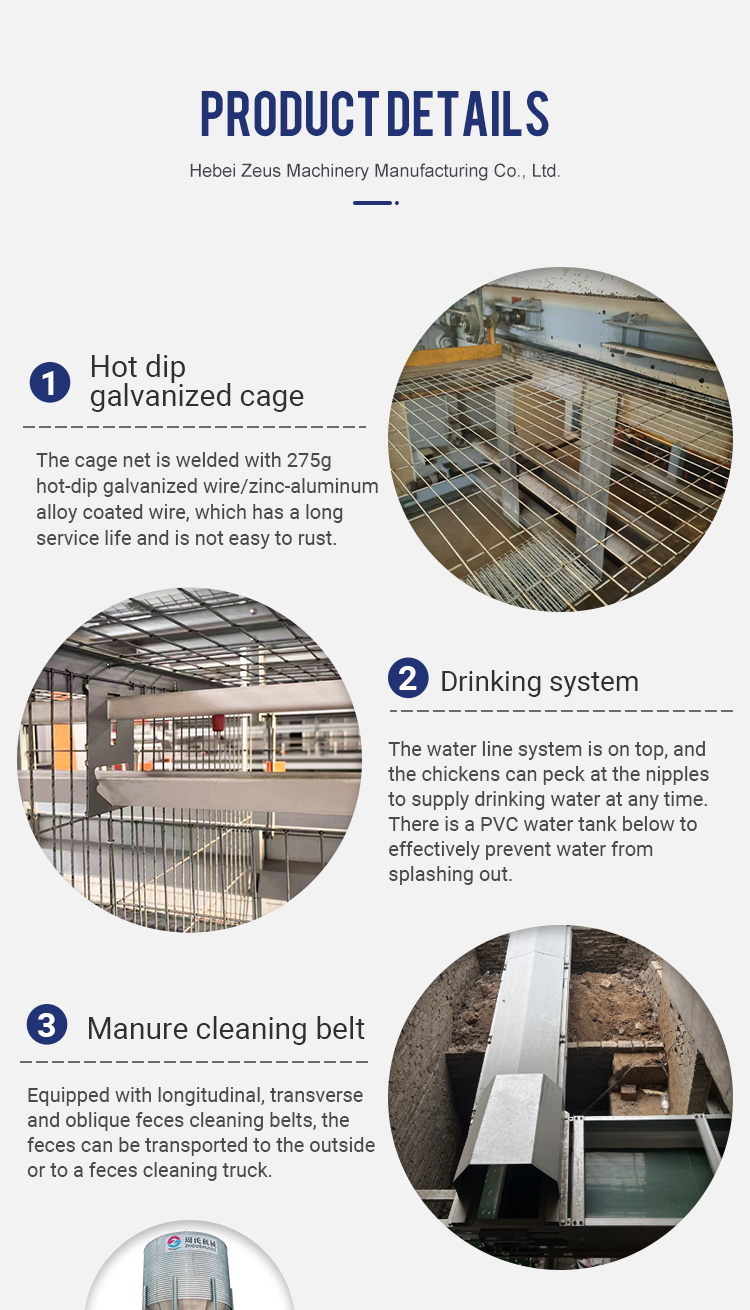

Material: hot dip galvanized surface

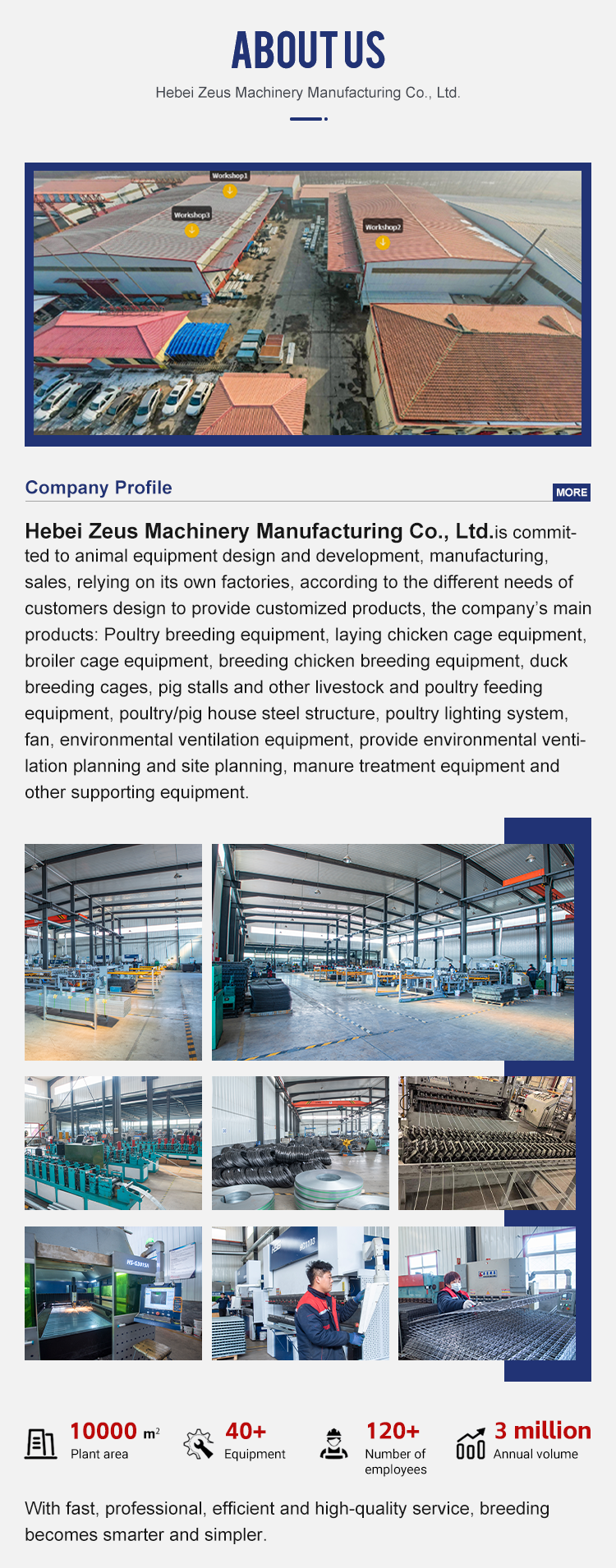

With fast, professional, efficient and high-quality service, breeding becomes smarter and simpler.

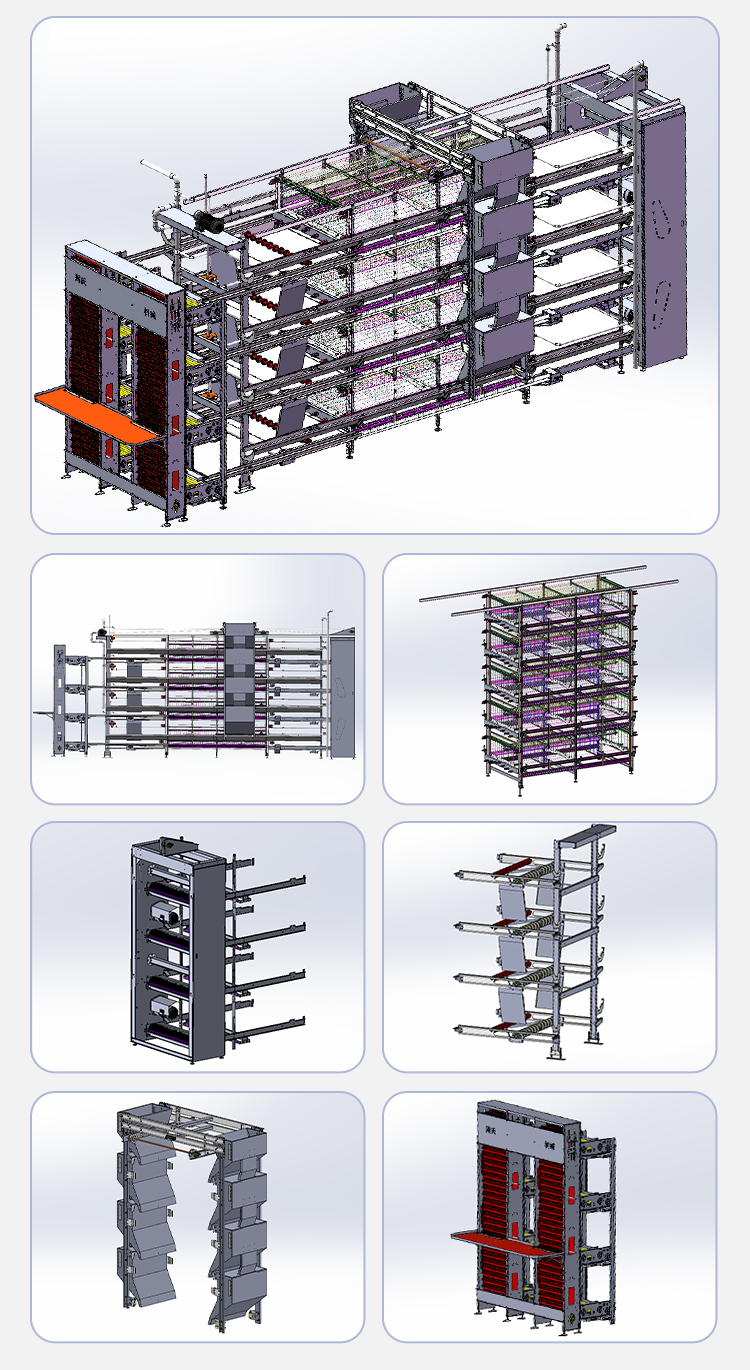

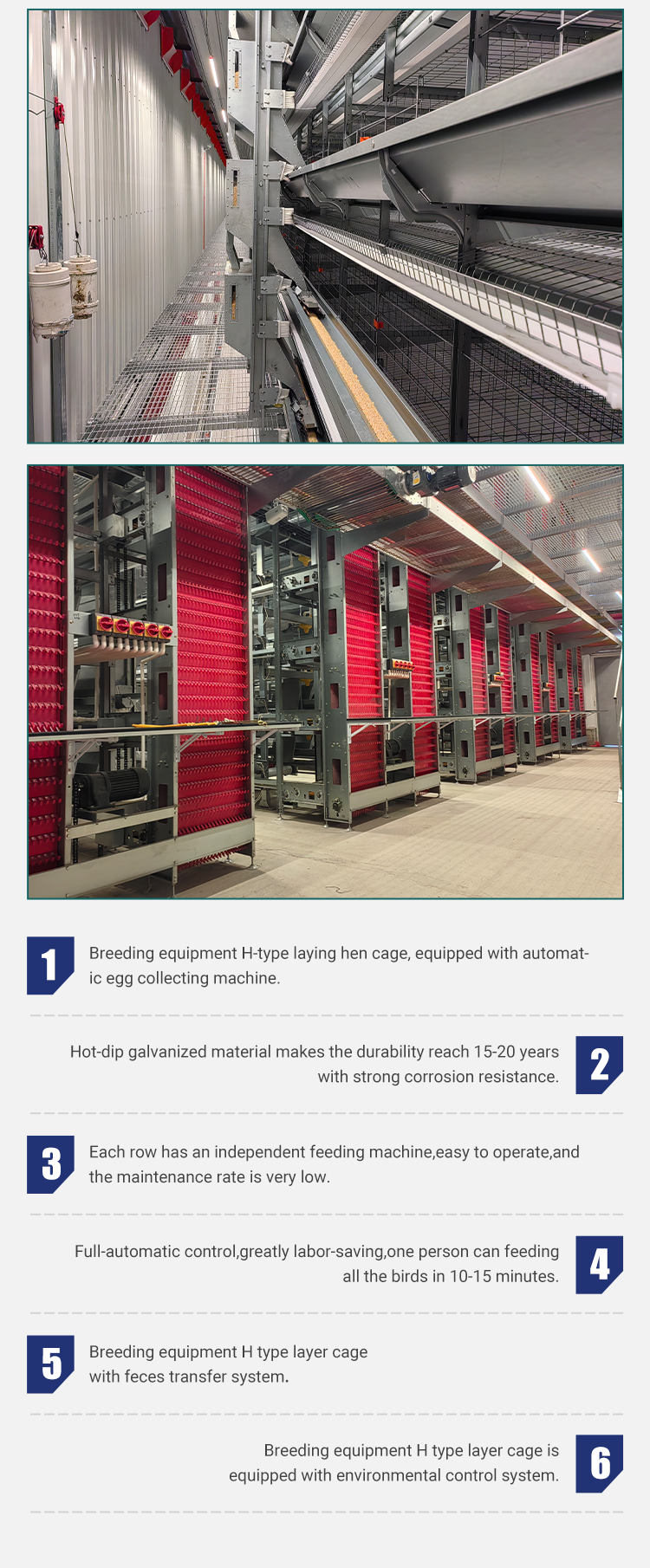

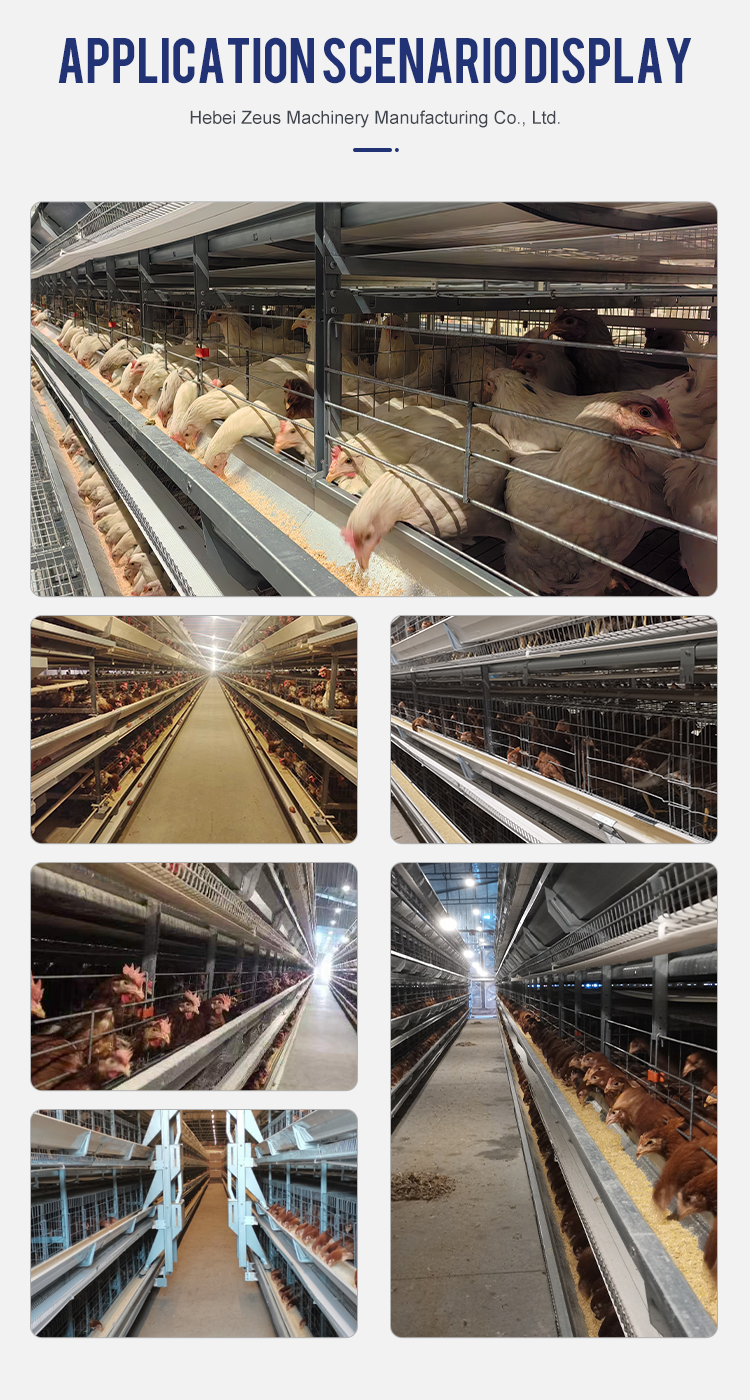

Stacking type laying hen breeding equipment

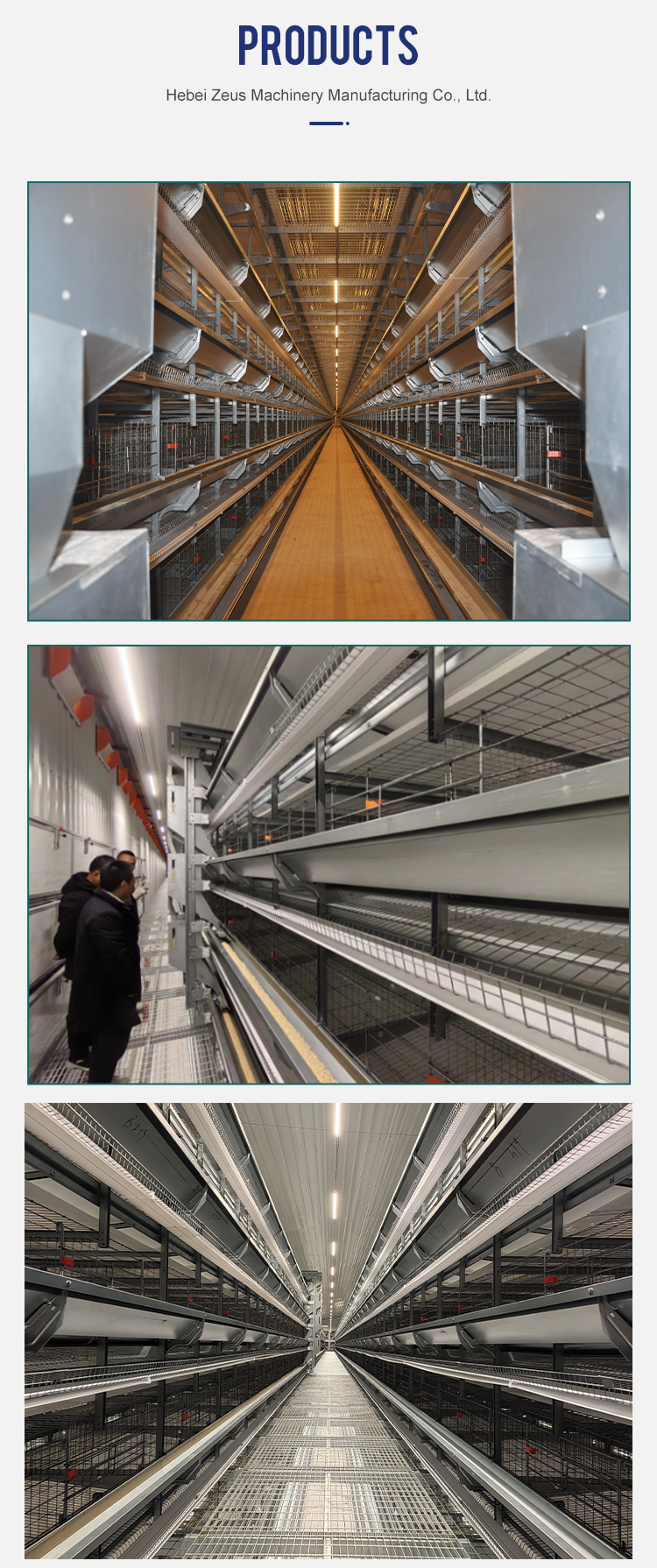

The stackable layer cage system is stacked in layers for easy management. The entire system is constructed of hot-dip galvanized material. Sufficient spacing between cages ensures ventilation, thereby reducing the birds’ internal temperature. The system is also easy to clean, ensuring a hygienic and comfortable living environment for the birds. A manure conveyor collects manure at the end of the coop and transports it outdoors via a horizontal manure conveyor. The system is equipped with a fully automatic climate controller, which uses a computer to calculate optimal ventilation to ensure good air quality in the coop. The system is operating normally. An audible and visual alarm system allows for monitoring of the water supply system.

Cascade laying hen breeding equipment consists of:

1. Automatic feeding system

The feeder features uniform feeding, low noise, energy conservation, and durability. The feeder is equipped with wheels to reduce friction between the feeder and the feed trough, extending its service life. The feed rate can be adjusted according to the age of the chickens, saving feed and labor, and operating smoothly and quickly. The feeder is self-propelled and automatically shuts down if a malfunction occurs, eliminating the problem of damage to the cage frame caused by traction feeders. The cutting amount can be easily adjusted by directly adjusting the material level.

2. Automatic feces cleaning system

The rear end drive shaft is made into a bidirectional spiral shape to solve the problem of deflection; the manure conveyor belt towing adopts a warped edge design to solve the problem of manure overflow.

3. Automatic drinking water system

The water pipe is designed to be installed in the middle of the cage, and a PVC water tank is installed under the pipe to prevent water droplets from splashing onto the chickens or feces.

4. Automatic temperature control system

We provide clients with personalized research and services for different projects. Through a series of computerized operations, we ensure a constant temperature and good ventilation in the poultry house, and manage and control the growth process of livestock and poultry.

5. Automatic egg collection system

Eggs are transported to the egg-picking machine at the front of the chicken house via an egg-laying conveyor belt, and then to the central egg collection line. The eggs are transported from the chicken house to the warehouse and packaged centrally in the warehouse, reducing the number of people entering the chicken house and reducing viral infection.