Menu

Close

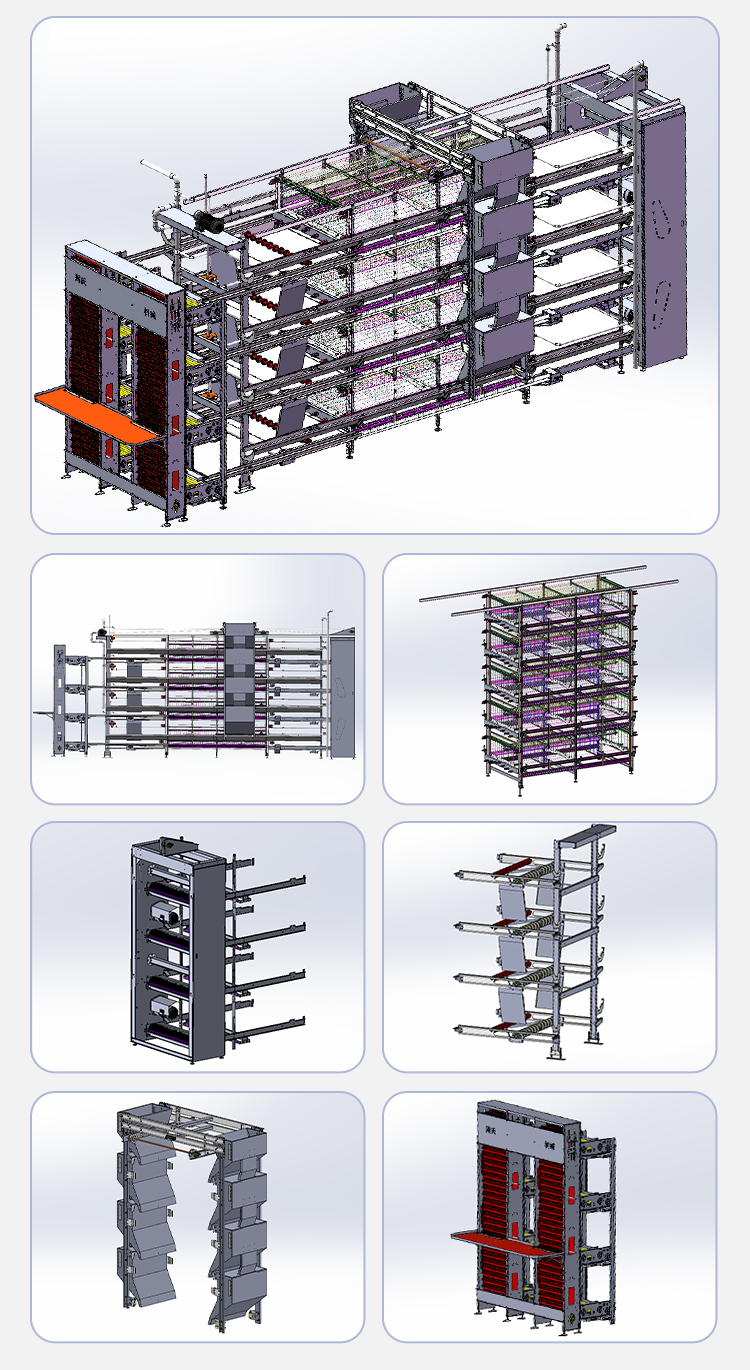

Material: Hot dip galvanized surface

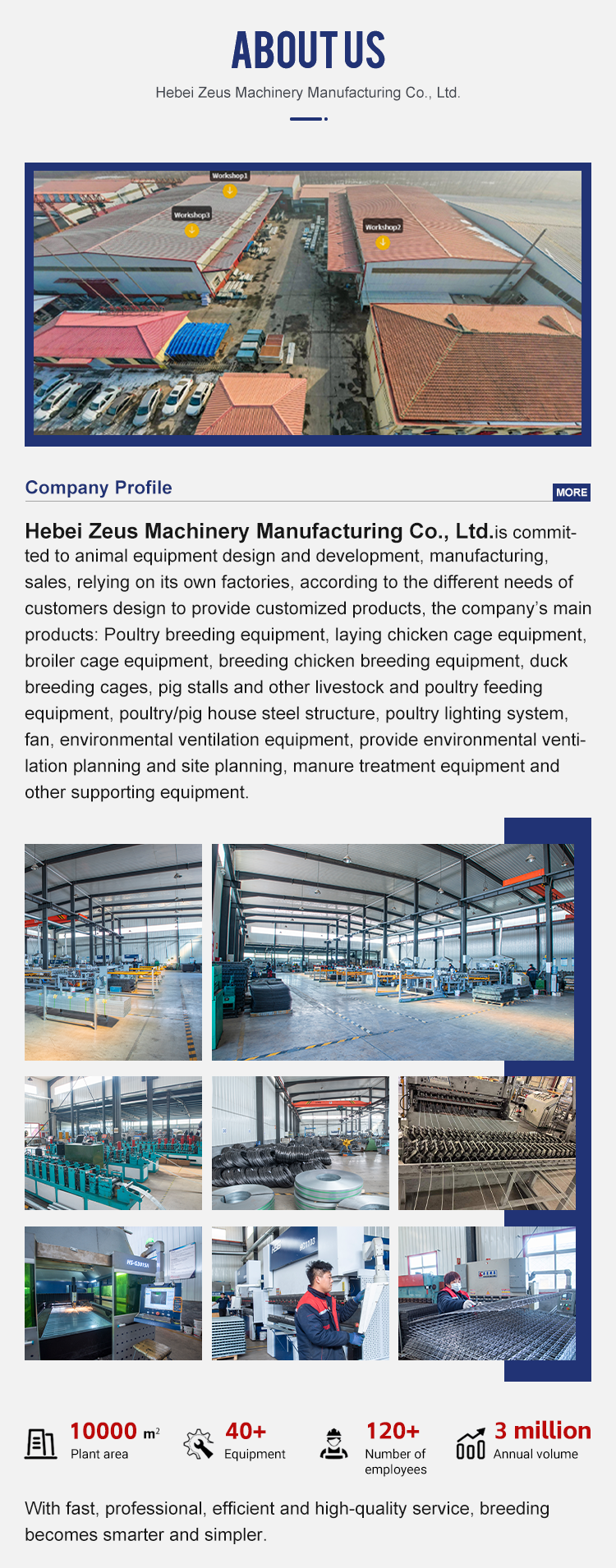

With fast, professional, efficient and high-quality service, breeding becomes smarter and simpler.

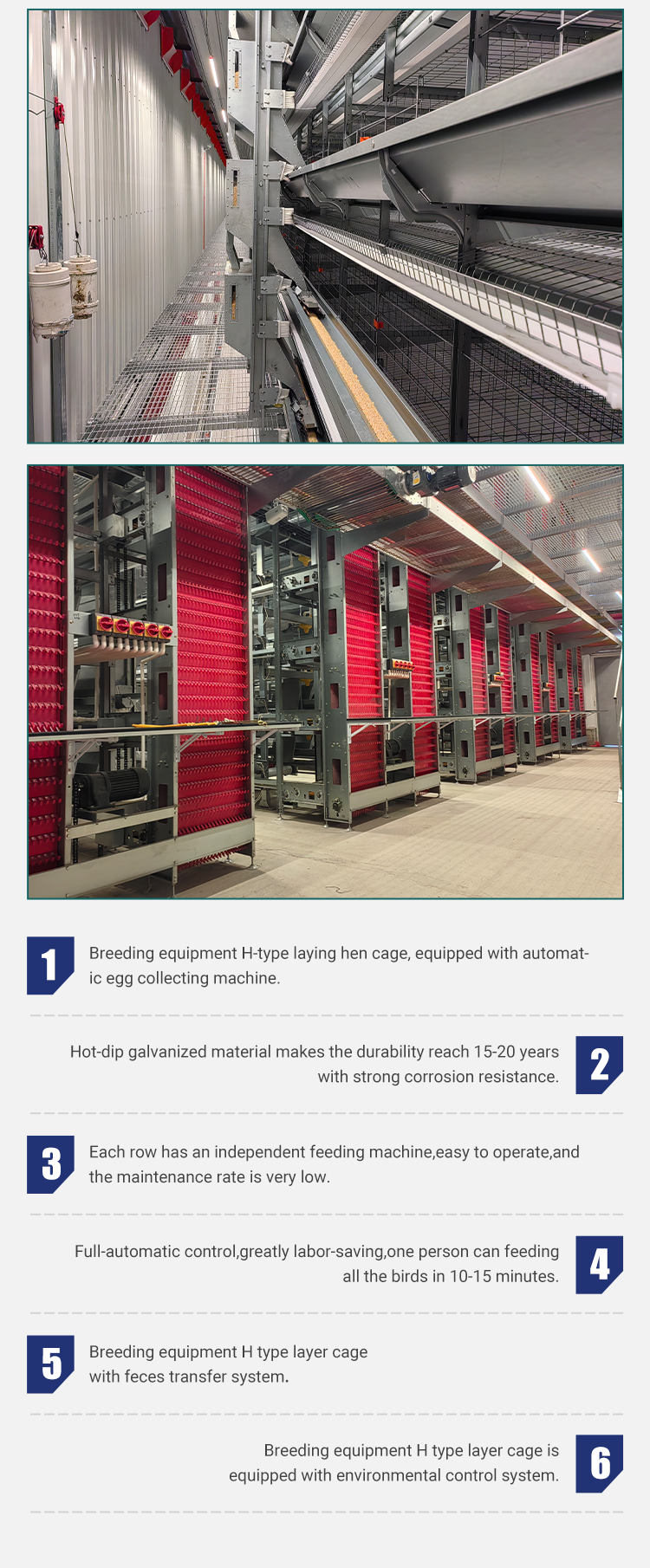

Stacked chicken cage product features:

1. The mesh of the laminated chicken cage is relatively smooth, which can prevent chicken claws from being injured and infected.

2. The partition nets and bottom nets of the stacked chicken cages are encrypted to avoid feather pecking and anal pecking and laying hen fatigue syndrome.

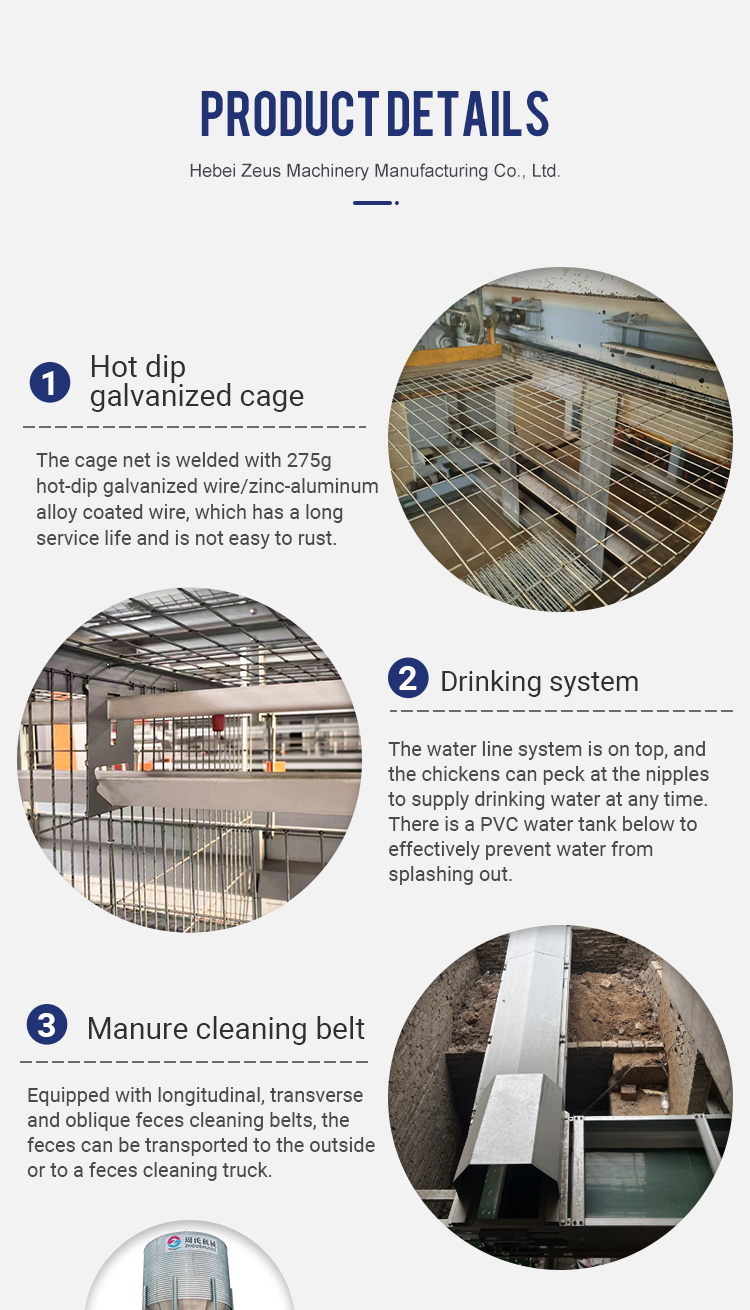

3. The laminated chicken cage mesh is welded with 275g hot-dip galvanized wire or galvanized aluminum alloy wire, which can extend the service life and is durable.

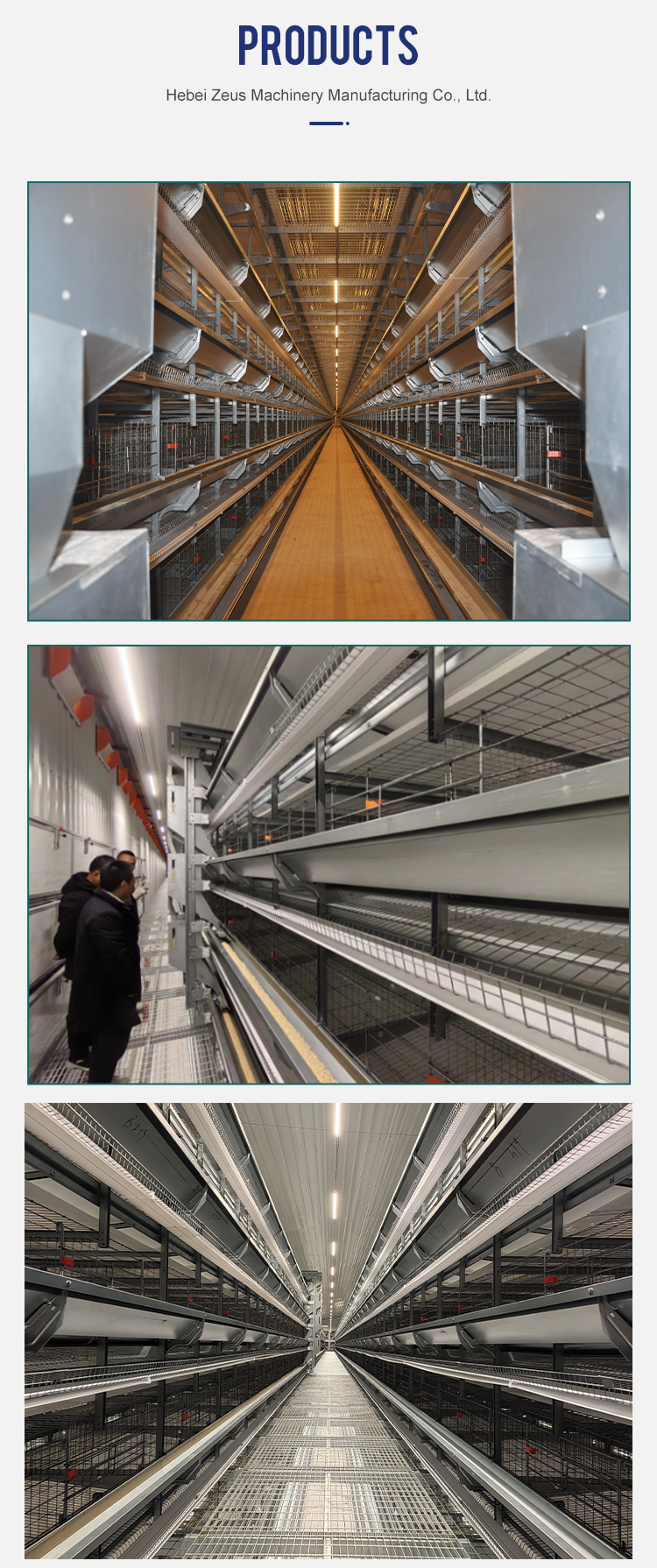

4. The high-density breeding of stacked chicken cages saves land, is conducive to epidemic prevention operations, and can also reduce the occurrence of problems.

5. The unique cage door reinforcement design of the stacking layer cage can effectively prevent the chickens from shaking when feeding and wasting feed. In addition, due to the large cage door space, it is easy to manage.

6. The main frame columns are made of 2.0mm thick 275g hot-dip galvanized sheet in a whole roll, with high consistency and high strength; easy installation and high firmness.

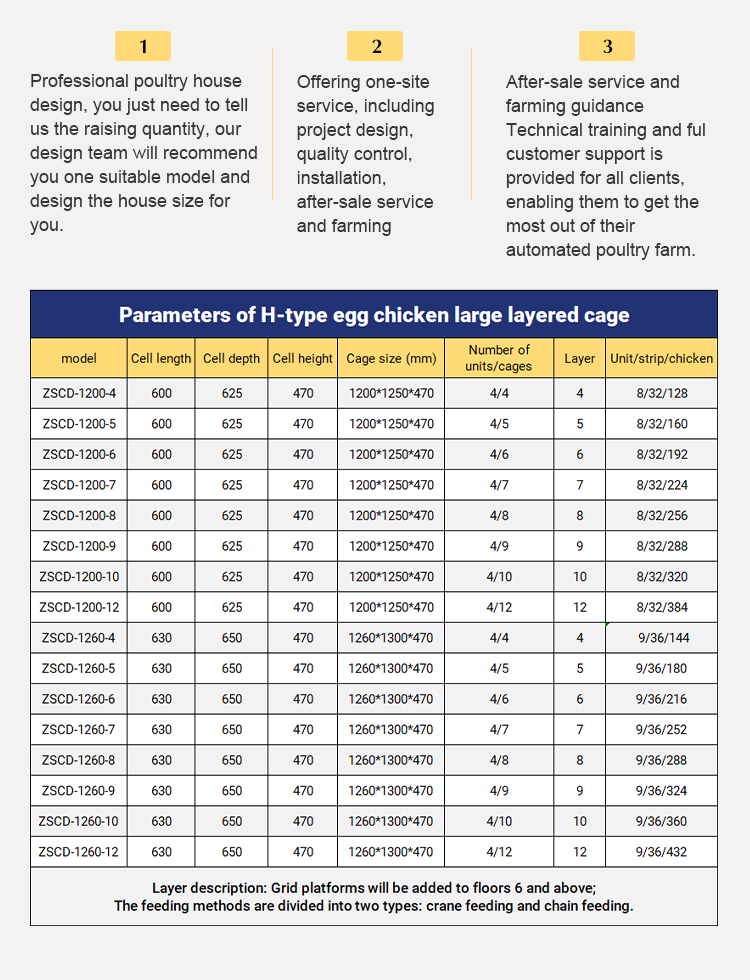

7. The cage specifications are 1200×1250mm and 1260×1300mm; taking the conventional four-layer cage as an example: it can raise 128 and 144 chickens; the area per chicken is 468.75 square centimeters and 455 square centimeters respectively.

8. Full utilization of space and high efficiency. Generally, taking a four-layer cage as an example: a cage chicken with a width of 15 meters, a length of 100 meters, and a height of 4 meters can raise 48,000 to 51,120 chickens. If the height of the chicken house is increased, a single chicken house can raise 100,000 chickens.