Menu

Close

Material: Hot dip galvanized surface

With fast, professional, efficient and high-quality service, breeding becomes smarter and simpler.

The stacked broiler cage is generally composed of 3 to 4 layers of chicken cages, which are completely overlapped. The chicken manure of each layer is transported to the horizontal manure belt at the tail end through the manure belt, and then transported to the outdoor manure collection truck. As the age of the chicks changes, the height of the adjustment plate and the water line height can be flexibly adjusted to ensure the supply of feed and drinking water for broilers of all ages, and avoid the phenomenon of “chicken running” and inappropriate drinking water height in the early stage of chicks. Stacked cage broilers are not only easy to observe, manage and disinfect, but also make full use of space. As long as the breeding environment of broilers can be controlled well, the feed-to-meat ratio will be significantly reduced, the occurrence of diseases will be significantly reduced, and the production efficiency will be significantly improved.

Cage specifications: broilers: There are three types of cages at this stage. The first type is 3-4 layer stacked cage equipment, with a cage length of 1250mm, a cage depth of 1000mm, and a cage height of 450mm. The breeding capacity of a single group is 75-100 white-feathered broilers (96-128 small broilers), and 1500 square meters can breed 36,000-48,000 white-feathered broilers (46,000-61,000 small broilers); secondly, the cage is 1400mm long, 1000mm deep, 450mm high, and has 3-4 layers. The first type of cage equipment has a single-group breeding capacity of 84 to 112 white-feathered broilers (105 to 140 small broilers), and 1,500 square meters can breed 35,600 to 47,500 white-feathered broilers (44,500 to 59,300 small broilers); the second type of cage equipment is 1,400 mm long, 800 mm deep, and 450 mm high, with double-row cages and 3 to 4 layers of stacked cages. The single-group breeding capacity is 132 to 176 white-feathered broilers (168 to 224 small broilers), and 1,500 square meters can breed 43,500 to 58,000 white-feathered broilers (55,440 to 73,900 small broilers).

Breeding equipment system: cage system, automatic manure cleaning system, automatic water supply system, automatic feeding system, automatic ventilation system, environmental control system, lighting system, disinfection system, heating system, backup power generation system, etc.

Automated broiler breeding equipment

We design and supply automated broiler farming equipment, starting from the first day the chicks are born.

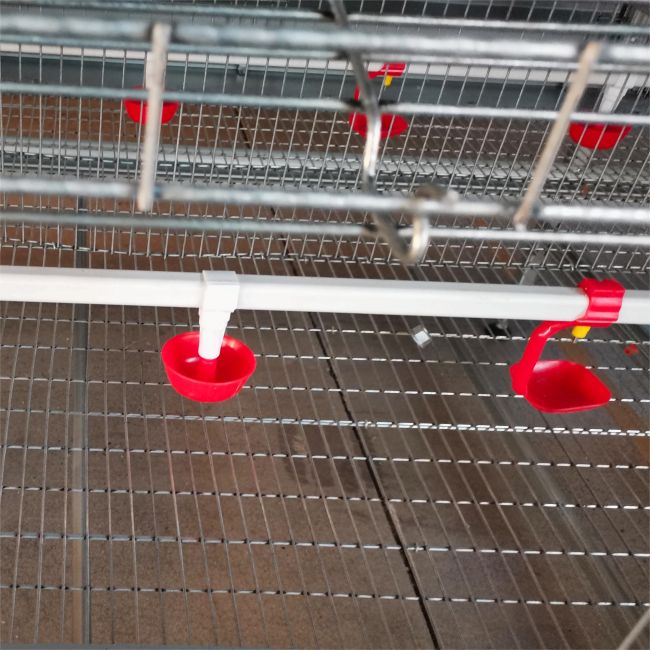

And throughout the entire growth cycle. The main equipment includes automatic drinking cups,

Poultry feeding systems, environmental control systems, lighting systems, manure cleaners, etc.

| Layered broiler equipment | ||||||

| Model | Cell length | Cell Depth | Cell height | Cage size (mm) | Cage layers | Total amount of breeding |

| ZSRJ-1-1250-3 | 1250 | 1000 | 450 | 1250~1000~450 | 3 | 75 |

| ZSRJ-1-1250-4 | 1250 | 1000 | 450 | 1250~1000~450 | 4 | 100 |

| ZSRJ-1-1400-3 | 1400 | 1000 | 450 | 1250~1000~450 | 3 | 84 |

| ZSRJ-1-1400-4 | 1400 | 1000 | 450 | 1250~1000~450 | 4 | 112 |

| ZSRJ-2×1400-3 | 1400 | 1400 | 450 | 1250~1000~450 | 3 | 117 |

| ZSRJ-2×1400-7 | 1400 | 1400 | 450 | 1250~1000~450 | 4 | 156 |

| Number of layers: 6 layers and above will have a grid platform; the material loading methods include crane loading and chain loading. |

||||||

Cage size: perfectly matched to the number of birds (stocking density: 50kg/㎡).

Surface treatment: hot-dip galvanizing, the thickness of the galvanized layer is 275g, uniform, and has good anti-corrosion performance.

Feed silo: includes weighing device to record daily feed consumption. Feed pan feeding: height is

It can be adjusted to feed chickens of different ages.

This mechanism ensures even distribution of feed throughout the system.

A lifting system on each drinker allows the birds to drink at the correct height.

Each cage is equipped with a water supply pipe and a drinking fountain, and 360° nipple water supply.

Supplied with dosators, filters and pressure gauges.

The device is linked with the manure cleaning belt under each cage to automatically clean the manure.

By operating the control cabinet, the feces can be discharged to the outside. It can be opened or closed at the same time.

Q1: I am interested in your poultry equipment.

What is the optimal price per unit?

A1: Please tell us the following basic information for reference so that we can recommend

The right choice and we will give you the right price accordingly:

(a) What are the dimensions of your chicken coop? The price is directly related to the size.

Because some parts are quoted by length and some are quoted by line.

(b) How many birds do you want to keep?

(c) Do you raise broiler chickens or laying hens?

Q2: My chicken coop has not been built yet, can you give us some advice?

A2: OK. Please build according to the plan.

If you have enough land, we can suggest a house size based on your preferences.

Q3: This is my first time importing, can you ship it?

Will the goods be shipped to my address?

A3: No problem. We can send the products to where you want.

Q4: I am concerned about the installation of poultry equipment.

Can you help me?

A4: Yes, we can. We will send the brochure and video for free for your reference.

We can also share instructions online; overseas installation teams are available for a fee.

Question 5: I plan to become a poultry farming equipment retailer

In the meantime, can you give me some support?

A5:Yes, we can. We will provide technical support to our agents for free. Discount price is also available based on quantity.