Menu

Close

Material: Surface hot-dip galvanizing Function: Egg chicken breeding Specifications: 1950×400×440mm Customizable Layers: 3-4 layers Breeding capacity: 3~5 chickens per door Area per chicken: not less than 450cm² Certification: ISO9001 Production capacity: 15 -20 years Sales method: Wholesale Customization: Support customization Minimum order quantity: 50 sets Origin: China

With fast, professional, efficient and high-quality service, breeding becomes smarter and simpler.

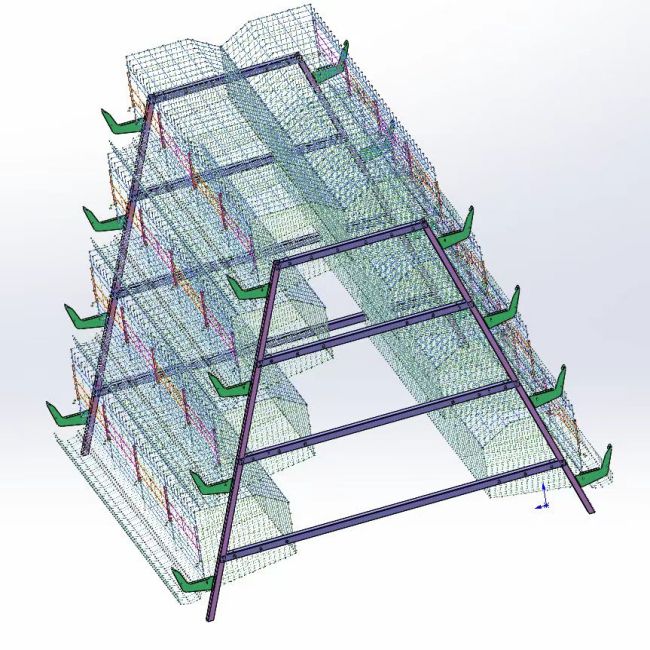

Product Introduction: Type A laying hen cage system has the characteristics of simple structure, easy operation and maintenance, diverse selection of automation equipment, low investment cost and quick results. Customers can choose pure chicken cage, semi-automatic or highly automated equipment according to different needs.

A-type laying hen cage cold galvanizing or full hot dip galvanizing equipment, with its own wire drawing production line, cage wire production, automatic cage mesh welding, cutting, bending, cage and cage leg frame cold / hot dip galvanizing, can control standards and quality. A-type laying hen cage is a very popular type of chicken cage on the market. It is relatively cheap and suitable for chicken houses with less than 25,000

| Ladder (Type A) laying hen cage parameters | |||||||

| Model | Cell length | Cell depth | Cell height | Cage dimensions (mm) |

Number of units /cages per cage |

Number of layers |

Number of chickens per unit/piece/group |

| LA1800-4-3 | 450 | 400 | 380 | 1800*400*380 | 4/6 | 3 | 4/16/96 |

| LA1800-4-4 | 450 | 400 | 380 | 1800*400*380 | 4/8 | 4 | 4/16/128 |

| LA1800-4-3 | 450 | 400 | 410 | 1800*400*410 | 4/6 | 3 | 4/16/96 |

| LA1800-4-4 | 450 | 400 | 410 | 1800*400*410 | 4/8 | 4 | 4/16/128 |

| LA1950-5-3 | 390 | 350 | 380 | 1950*350*380 | 5/6 | 3 | 3/15/90 |

| LA1950-5-4 | 390 | 350 | 380 | 1950*350*380 | 5/8 | 4 | 3/15/120 |

| LA1950-5-3 | 390 | 400 | 410 | 1950*400*410 | 5/6 | 3 | 3/15/90 |

| LA1950-5-4 | 390 | 400 | 410 | 1950*400*410 | 5/8 | 4 | 3/15/120 |

| LA2000-5-3 | 400 | 450 | 410 | 2000*450*410 | 5/6 | 3 | 4/20/120 |

| LA2000-5-4 | 400 | 450 | 410 | 2000*450*410 | 5/8 | 4 | 4/20/160 |

| Our product parameters accept customization | |||||||