- +86 15030729981

- hebeizeus@163.com

- Economic Development Zone, Cang City, Hebei Province, China

Material: Hot dip galvanized surface

With fast, professional, efficient and high-quality service, breeding becomes smarter and simpler.

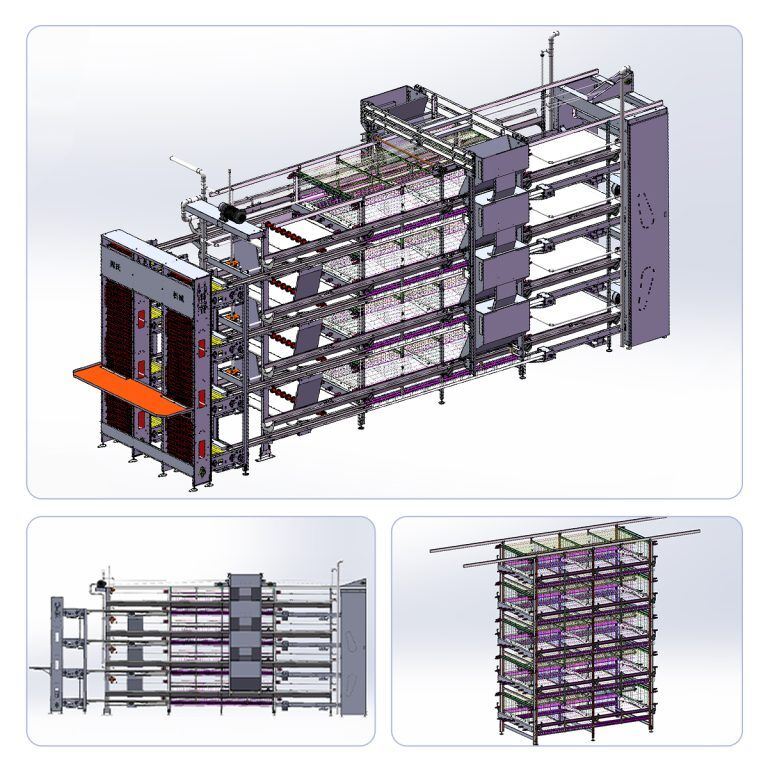

Small laying hen stacking equipment usually consists of cages, cage doors, feeding and conveying systems, manure cleaning systems, automatic egg collection systems, etc. The following is a detailed introduction to each part:

-Cage body: The main body has a variety of specifications and can be selected according to the actual situation of the user. The bottom net of the chicken cage requires moderate strength and elasticity, and a reasonable egg rolling angle to meet the technical requirements of comfortable walking of chickens, stable egg rolling, low egg breakage rate, and low dirty egg rate.

– Cage door: Generally adopts horizontal sliding door design, which is easy to open and can prevent chickens from escaping.

– Conveying feeding system: The feeding carriage is operated by remote control or button, and stops automatically when it reaches the end of each row of cages. During operation, the hoppers on each layer of the carriage will correspond to each trough one by one, and the feed will fall evenly on the trough for the chickens to eat freely.

– Manure cleaning system: There is a longitudinal manure cleaning belt under each layer of chicken cages. Under the action of longitudinal airflow, most of the moisture in the chicken manure can be taken out of the house, greatly reducing the moisture content of the chicken manure. It is cleaned out of the house through the control system.

– Automatic egg collection system: It is an important part of the stacked egg cage equipment. When collecting eggs at the front end, in order to achieve the best effect in the egg collection and transportation process, the system is equipped with a soft egg removal device, which can remove soft eggs and broken eggs before the eggs enter the egg collector, which can greatly save manpower and reduce the broken egg rate.

1. Professional poultry house design, you just need to tell us the raising quantity, our

design team will recommend you one suitable model and design the house size for you.

2. Offering one-site service, including project design, quality control, installation, after-sale

service and farming guidance.

3. After-sale service and farming guidance Technical training and ful customer support is

provided for all clients, enabling them to get the most out of their automated poultry farm.

| Parameters of H-type egg chicken large layered cage | |||||||

| model | Cell length | Cell depth | Cell height | Cage size (mm) | Number of units/cages | Layer | Unit/strip/chicken |

| ZSCD-1200-4 | 600 | 625 | 470 | 1200*1250*470 | 4/4 | 4 | 8/32/128 |

| ZSCD-1200-5 | 600 | 625 | 470 | 1200*1250*470 | 4/5 | 5 | 8/32/160 |

| ZSCD-1200-6 | 600 | 625 | 470 | 1200*1250*470 | 4/6 | 6 | 8/32/192 |

| ZSCD-1200-7 | 600 | 625 | 470 | 1200*1250*470 | 4/7 | 7 | 8/32/224 |

| ZSCD-1200-8 | 600 | 625 | 470 | 1200*1250*470 | 4/8 | 8 | 8/32/256 |

| ZSCD-1200-9 | 600 | 625 | 470 | 1200*1250*470 | 4/9 | 9 | 8/32/288 |

| ZSCD-1200-10 | 600 | 625 | 470 | 1200*1250*470 | 4/10 | 10 | 8/32/320 |

| ZSCD-1200-12 | 600 | 625 | 470 | 1200*1250*470 | 4/12 | 12 | 8/32/384 |

| ZSCD-1260-4 | 630 | 650 | 470 | 1260*1300*470 | 4/4 | 4 | 9/36/144 |

| ZSCD-1260-5 | 630 | 650 | 470 | 1260*1300*470 | 4/5 | 5 | 9/36/180 |

| ZSCD-1260-6 | 630 | 650 | 470 | 1260*1300*470 | 4/6 | 6 | 9/36/216 |

| ZSCD-1260-7 | 630 | 650 | 470 | 1260*1300*470 | 4/7 | 7 | 9/36/252 |

| ZSCD-1260-8 | 630 | 650 | 470 | 1260*1300*470 | 4/8 | 8 | 9/36/288 |

| ZSCD-1260-9 | 630 | 650 | 470 | 1260*1300*470 | 4/9 | 9 | 9/36/324 |

| ZSCD-1260-10 | 630 | 650 | 470 | 1260*1300*470 | 4/10 | 10 | 9/36/360 |

| ZSCD-1260-12 | 630 | 650 | 470 | 1260*1300*470 | 4/12 | 12 | 9/36/432 |

| Layer description: Grid platforms will be added to floors 6 and above; The feeding methods are divided into two types: crane feeding and chain feeding. | |||||||

Automated page speed optimizations for fast site performance