Menu

Close

Material: Hot dip galvanized surface

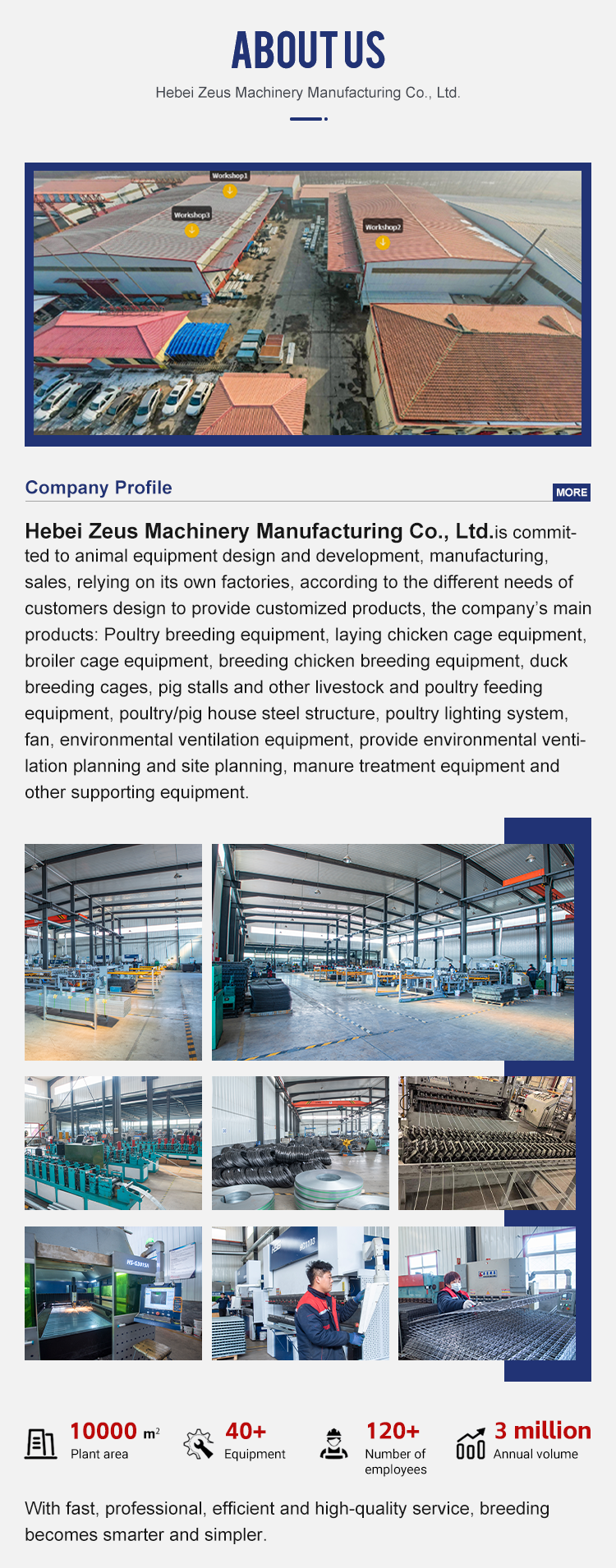

With fast, professional, efficient and high-quality service, breeding becomes smarter and simpler.

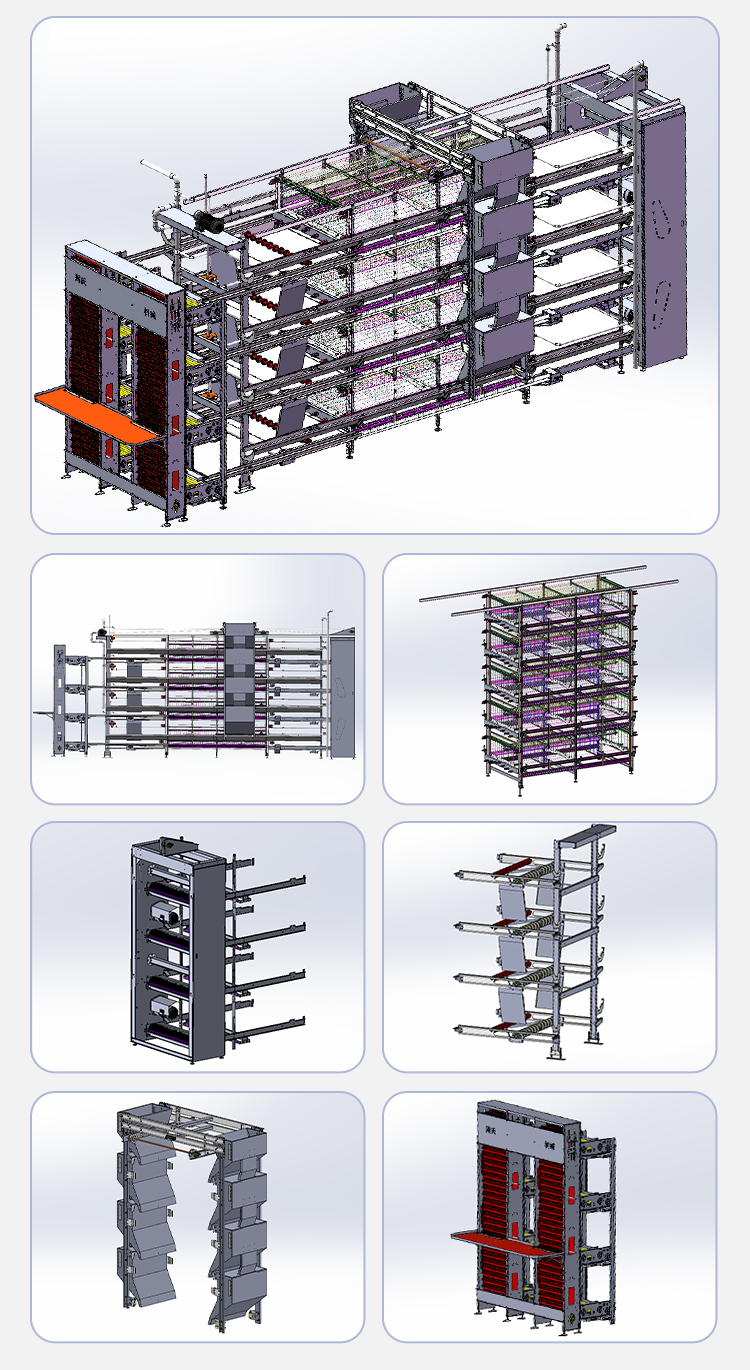

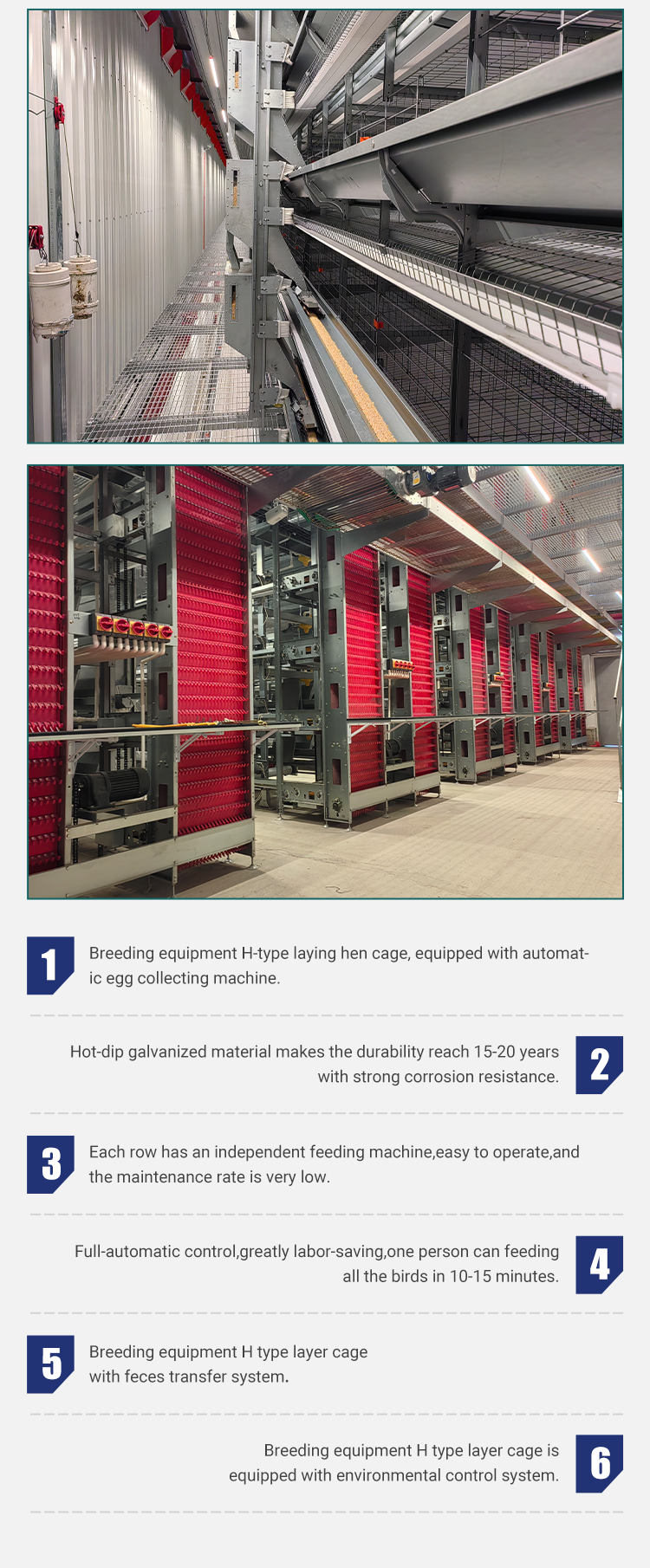

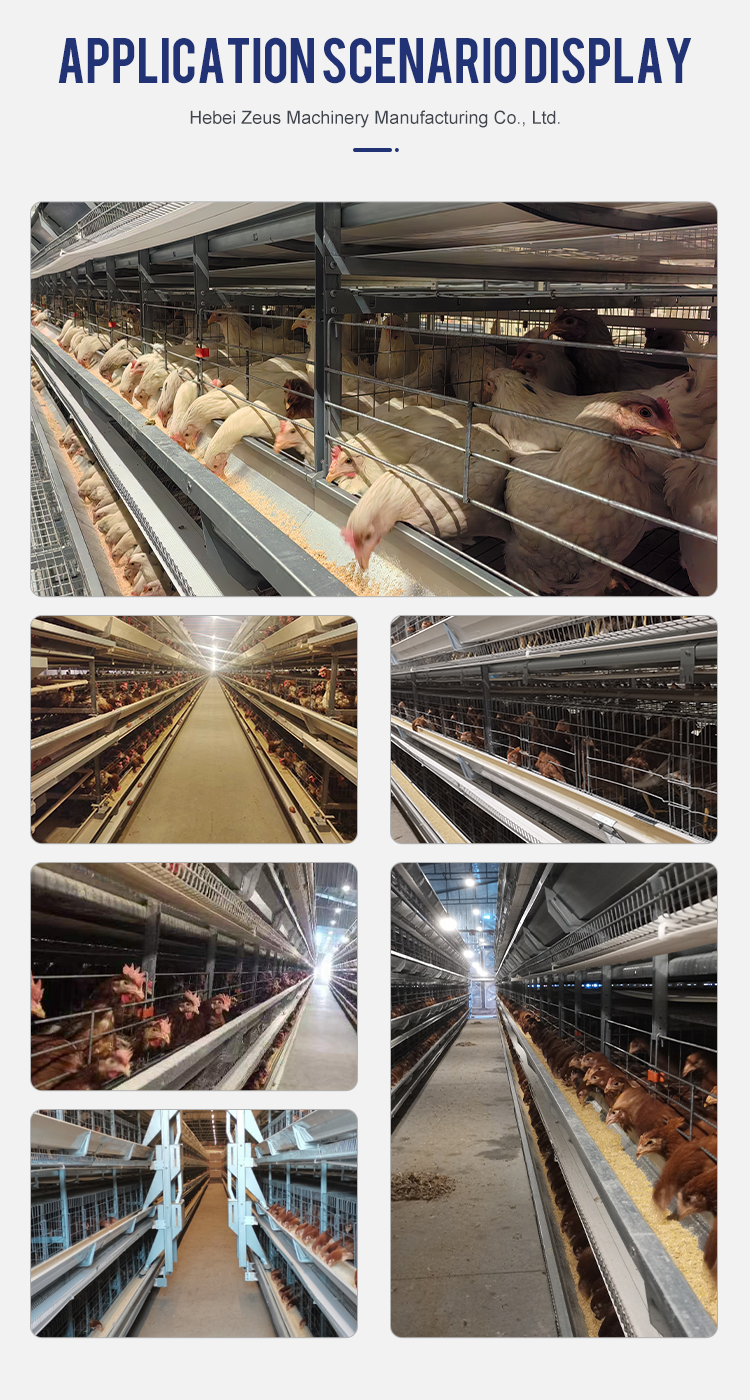

Stacked laying hen breeding equipment

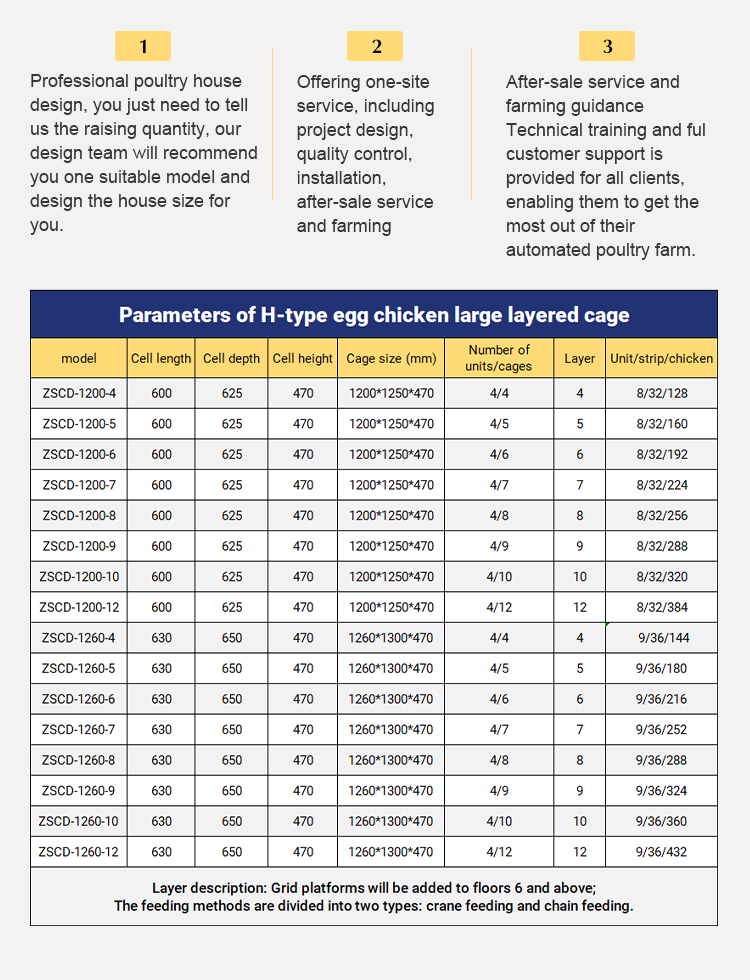

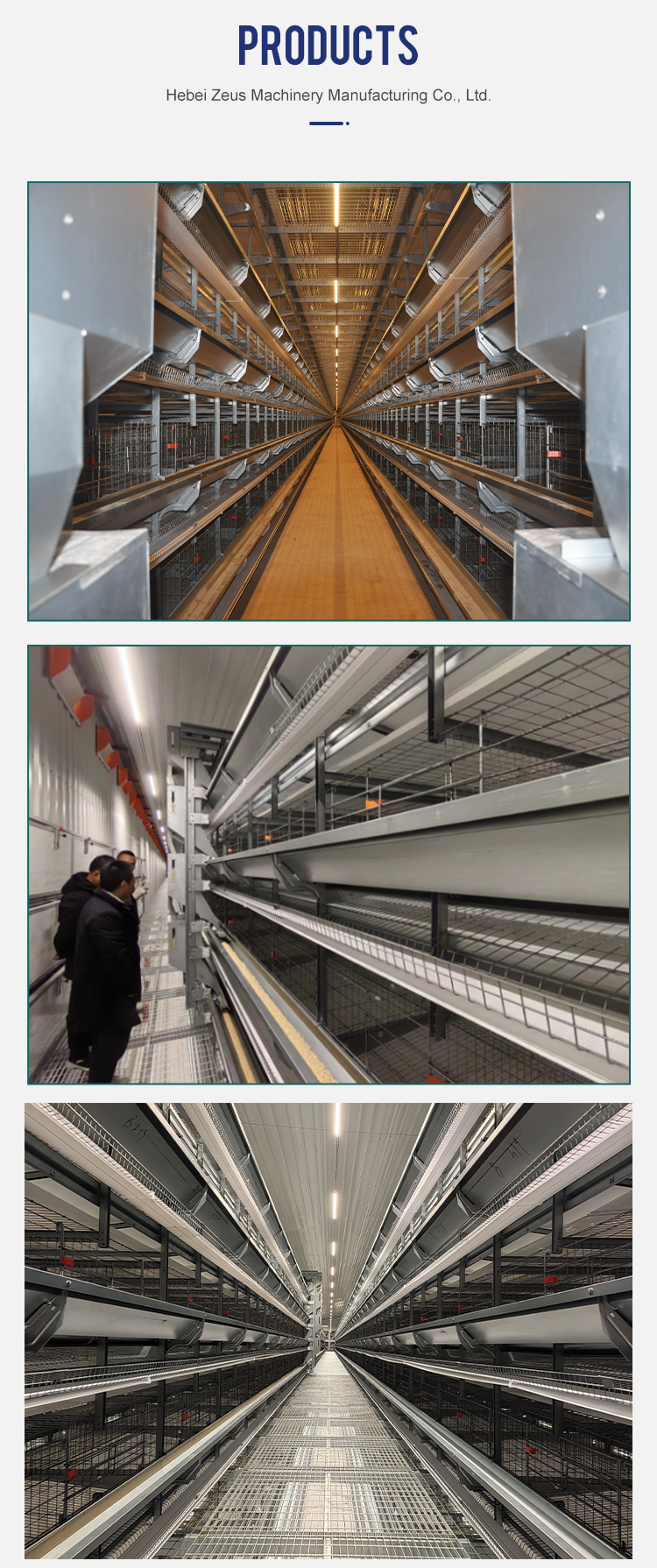

The stacked laying hen cage equipment is stacked layer by layer for easy management. The whole equipment is made of hot-dip galvanized material. There is enough distance between each layer of cages to ensure ventilation in the cage, thereby reducing the temperature of the chickens themselves. At the same time, the equipment is easy to clean, ensuring a hygienic and comfortable living environment for the chickens. The manure conveyor collects the manure at the end of the chicken house and transports it to the outside through the horizontal manure conveyor. The equipment is equipped with a fully automatic environmental controller, and the computer calculates reasonable ventilation to ensure good air in the chicken house. The equipment operates normally. The use of sound or light alarm devices can realize the supervision and control of the water supply system.

Components of cascading laying hen breeding equipment:

1. Automatic feeding system

Uniform feeding, low noise, energy saving, strong and durable; the feeder is equipped with wheels to reduce the friction between the feeder and the feed trough and extend the service life; the feeding amount can be adjusted according to the age of the chicken, saving feed and man-hours, and running smoothly and quickly. The feeder adopts a self-propelled design and can automatically stop when encountering a fault, solving the problem of cage damage caused by tractor-type feeder failure. The cutting amount is more convenient to adjust, and the thickness of the cut material can be adjusted by directly moving the material level. :

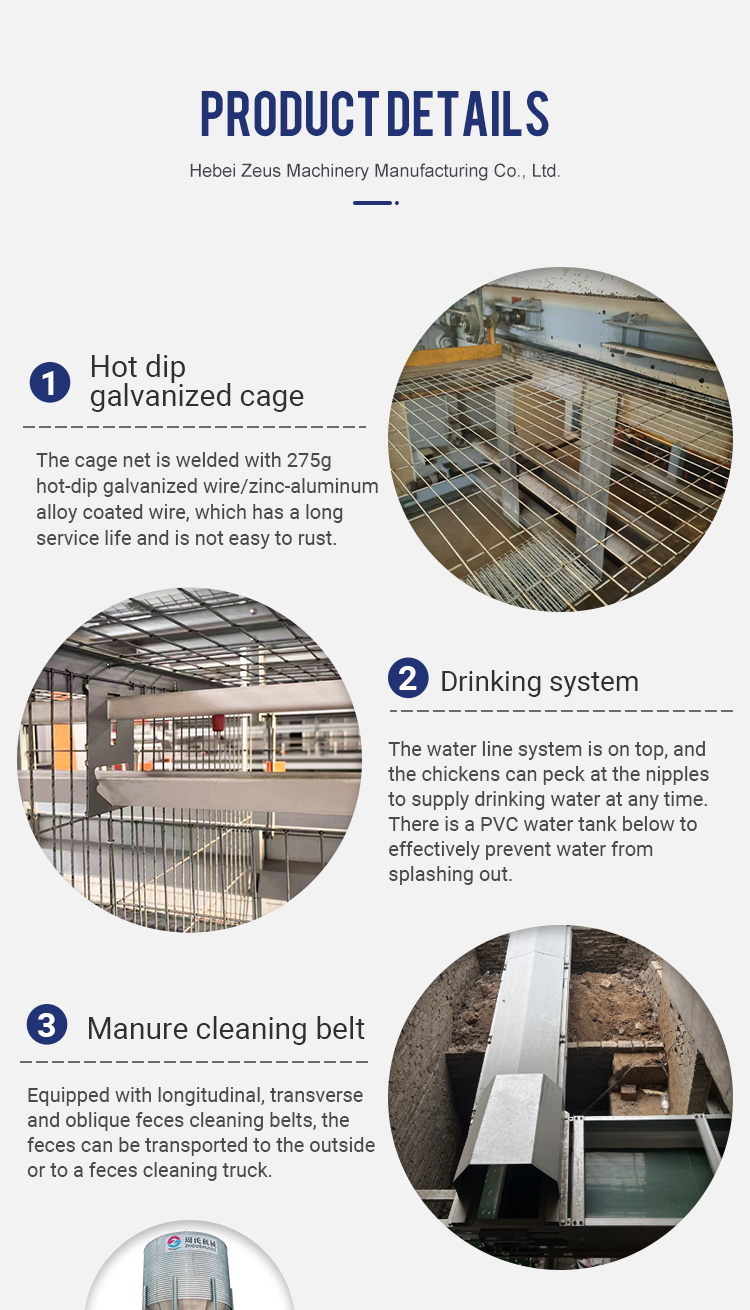

2. Automatic manure cleaning system

The rear-end transmission shaft is made into a bidirectional spiral shape, which solves the problem of deviation and curling; the manure conveyor belt drag strip adopts a warped edge design, which solves the problem of manure overflowing.

3. Automatic drinking water system

The water pipe is designed to be installed in the middle of the cage, and a PVC water tank is installed under the water pipe to prevent water droplets from splashing onto the chickens or feces.

4. Automatic temperature control system

We provide customers with personalized research and services for different projects. Through a series of computerized operations, we ensure that the poultry house has a constant temperature and good ventilation, and manage and control the growth process of poultry and livestock.

5. Automatic egg collection system

Eggs are transported by egg-laying conveyor belts to the egg picking machine at the front of the chicken house, and then transported to the central egg collecting line. The eggs are transported from the chicken house to the warehouse, where they are centrally packaged, reducing the number of people entering the chicken house and reducing virus infection.