Menu

Close

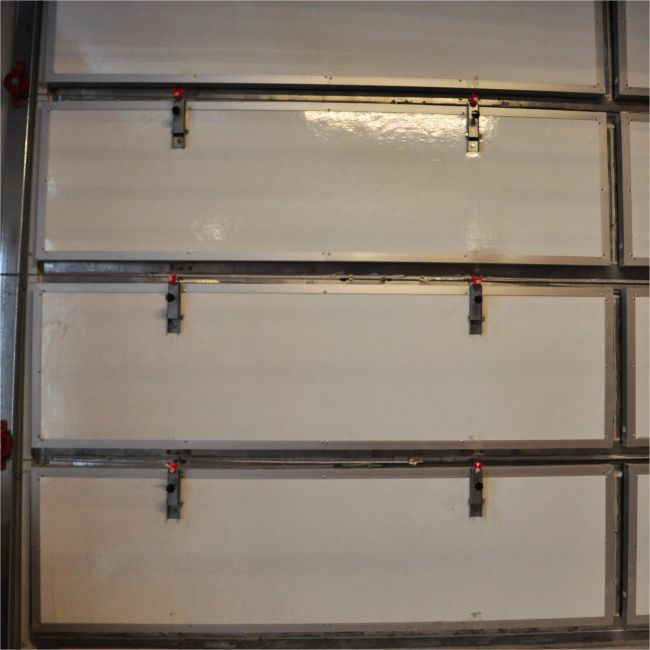

Material:Surface hot dip galvanized

With fast, professional, efficient and high-quality service, breeding becomes smarter and simpler.

Stacked cage broilers.

Specifications: 1250mm long*1000mm deep*450mm high; 1250mm long*800mm deep*450mm high;

1400mm long*1000mm deep*450mm high; 1400mm long*800mm deep*450mm high;

1400mm long*1200mm deep*450mm high; 1400mm long*1400mm deep*450mm high;

Material: 1. The cage frame is made of hot-dip galvanized steel plate, and the surface is galvanized at 275g/m².

2. The cage mesh is welded with 275g hot-dip galvanized wire; specifications include: cage length 1000-1500mm optional; cage depth 700-1500mm optional; cage height 420-450mm optional.

3. The trough is a white PVC trough specially used for broiler chickens; specifications: 5-9-13, 3.75 meters/root and 4.2 meters/root.

4. Water line: white water line. Special square tube specifications for broilers: 22*22mm, 3.75 meters/root and 4.2 meters/root; 3-4 nipple drinkers per cage, equipped with hanging cups, and steel wire lifting water lines.

Raising broilers in stacked cages can improve space utilization. Compared with traditional breeding methods, caged broilers can raise more broilers in a limited space, increasing the number of chickens in stock. At the same time, cage raising can also avoid collisions between chickens, reduce the injury rate of chickens, and ensure the health and safety of chickens.

Caged broilers have the advantage of saving feed. Caged broilers usually use automated feeding methods, which can avoid feed waste, reduce feed costs, and improve breeding efficiency. In addition, raising broilers in cages can also reduce the contact between chickens and chicken manure, reduce the number of bacteria in chicken manure, ensure the health of chickens, and reduce feed waste.